Sarus Lamp

SLS Nylon, PLA, Polystyrene, Aluminum, Steel, 2025

I made a task lamp inspired by my obsession with task lighting and Bauhaus design featuring a positional arm. This lamp allows the user to define their own experience with it, letting it be used to help perform a variety of different tasks. Made from a combination of handmade elements and 3D-printed components, the mechanism relies on spring tension, friction-fitted parts, and fasteners to remain stable. The lamp features an on-and-off switch in the base.

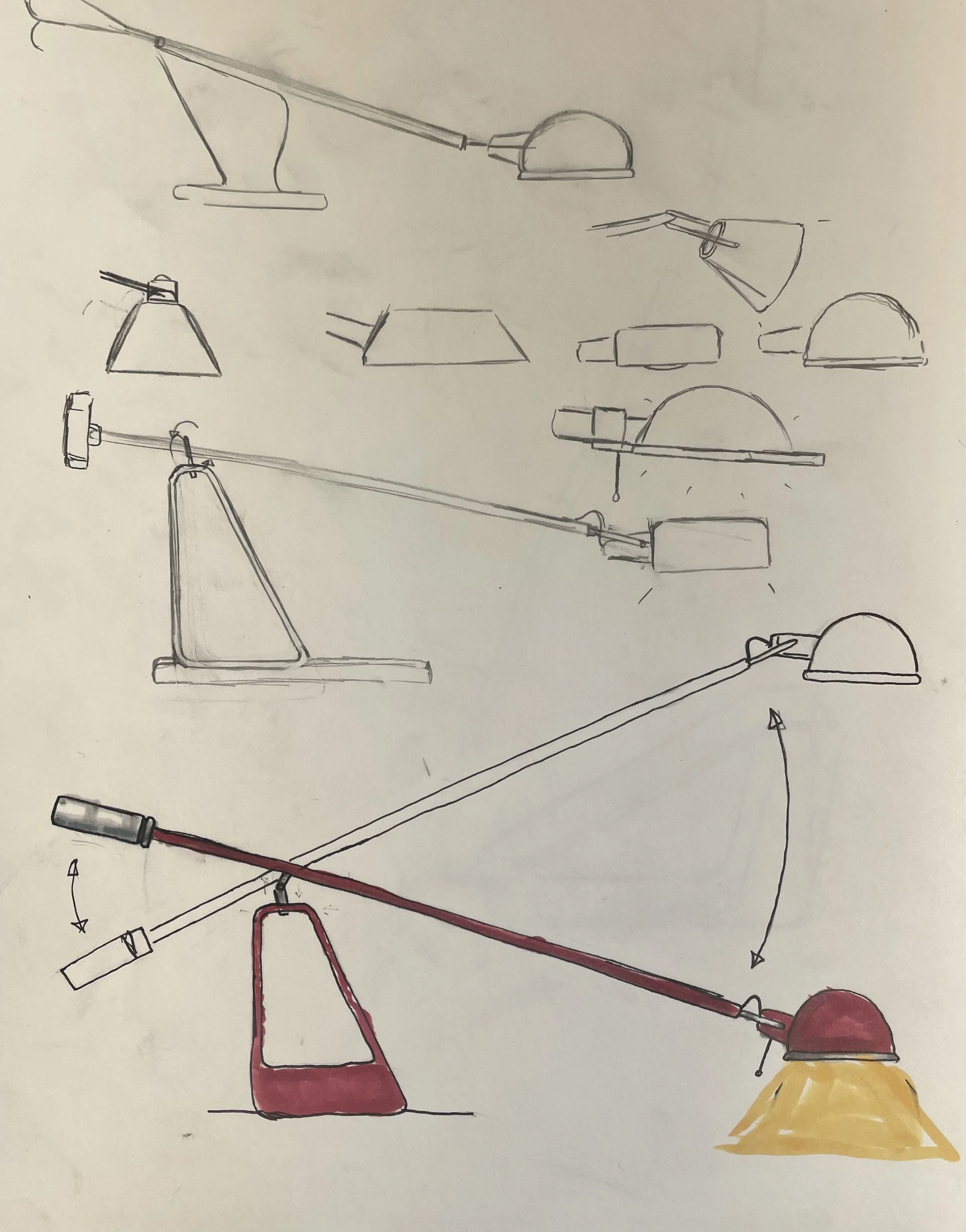

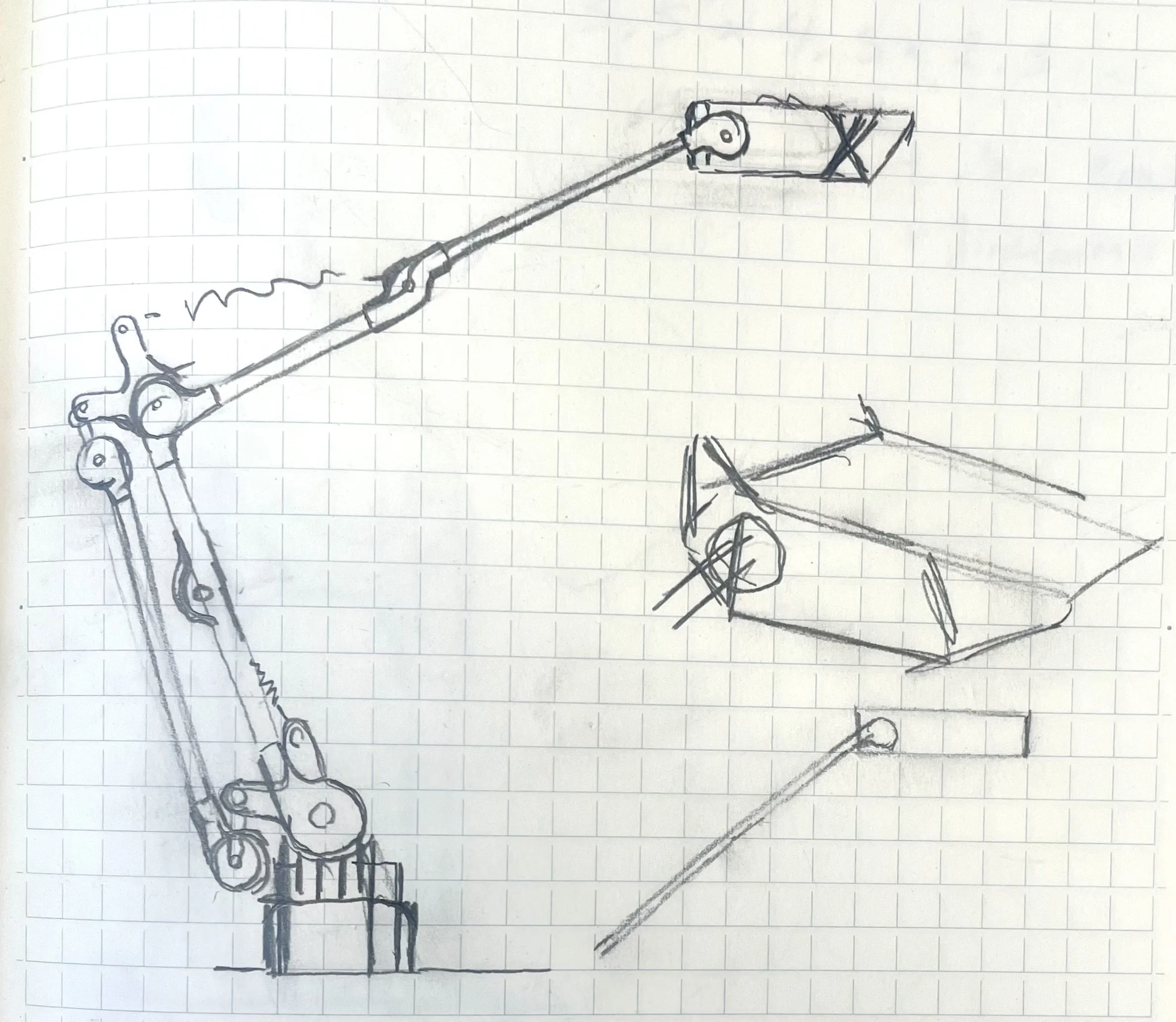

This project went through multiple stages of sketching, prototyping, and setbacks before its final iteration

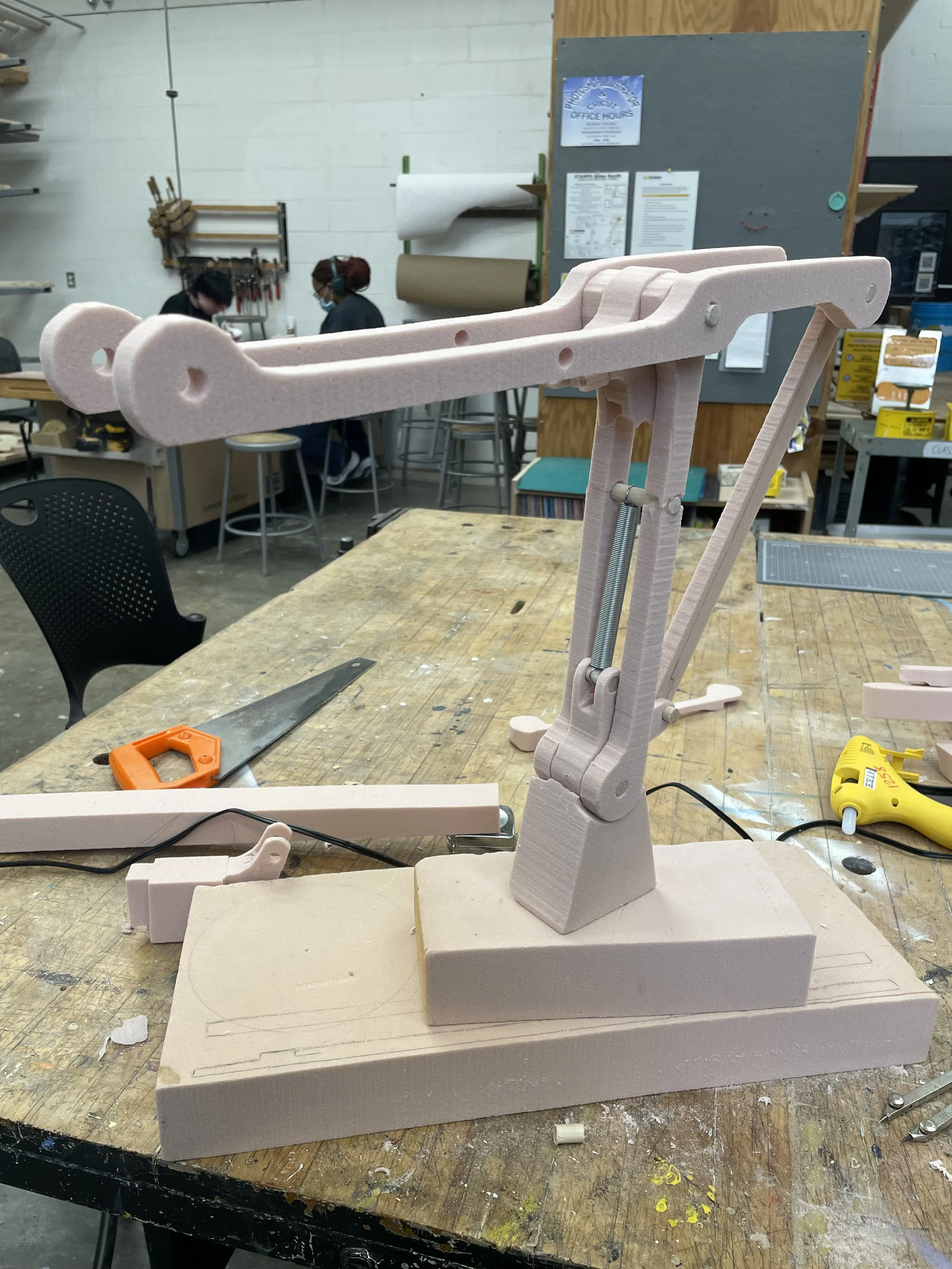

The first step with making came with making a foam prototype in the wood shop testing the mechanics experimenting with spring tension.

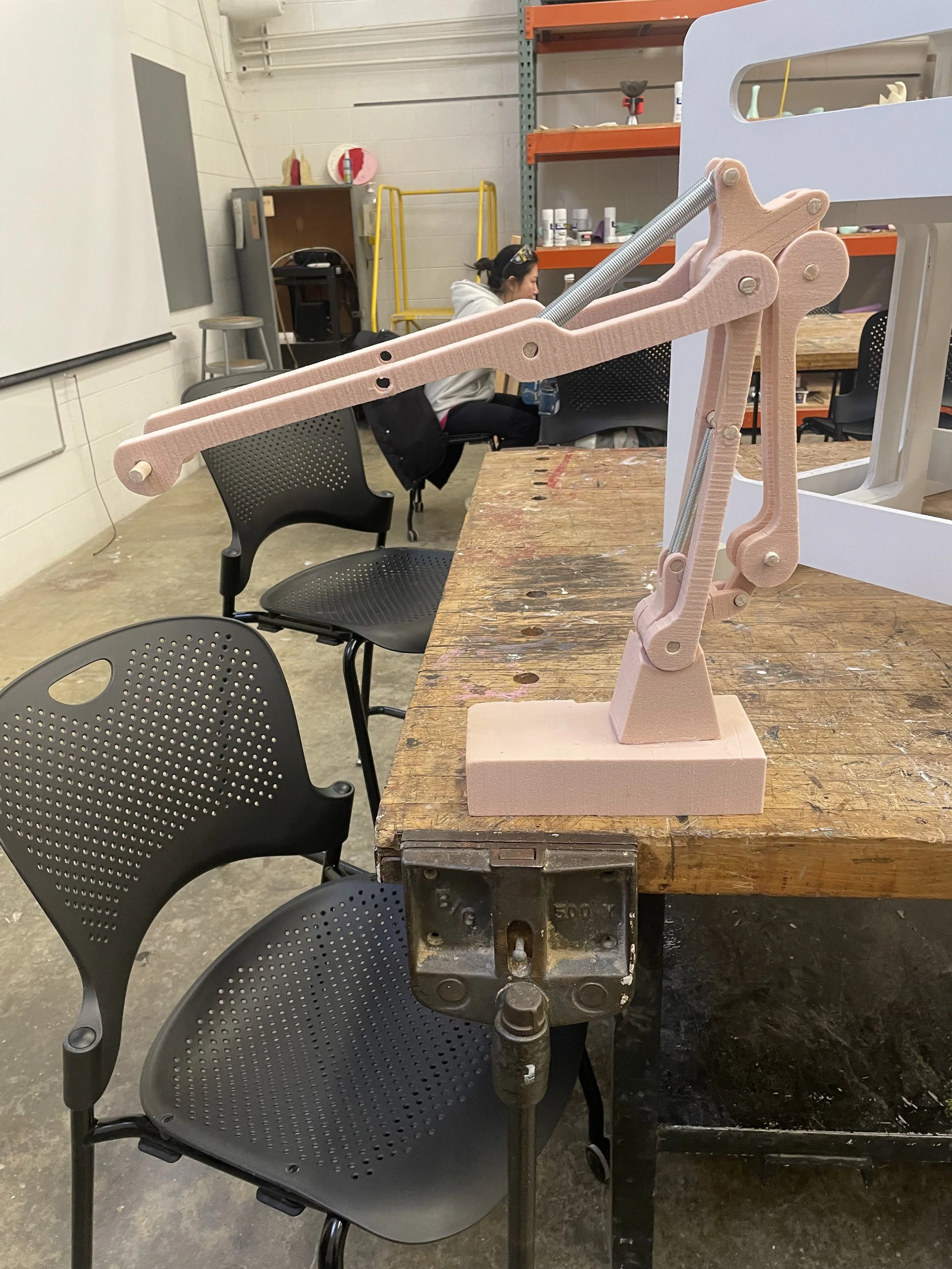

Once the foam prototype hand been finished I modeled each of the individual joints in CAD and 3D printed them in SLS Nylon and began test fitting them to aluminum.

There was a major setback from a design issue I had overlooked in how I had planned to attach the arm to the base, after the first part breaking I went back into CAD and made a replacement bracket that would fix it.

After some challenges with balancing the weight of the arm, I had a fully functional prototype and hand-fabricated the shade and base covering with polystyrene plastic.